Transforming Motion with Electrostatic Motors

Welcome to C-Motive

The World's First Commercially Available Electrostatic Machine.

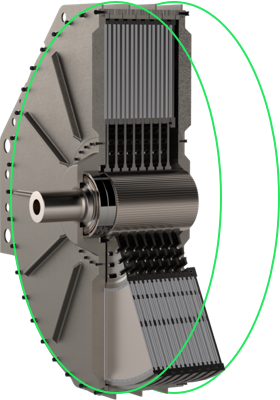

Electric motors have been around for almost 2 centuries and have witnessed few fundamental changes since their creation, until now. C-Motive Technologies is the first and only company commercializing sustainable, high-efficiency motor technology using electrostatic principles to decarbonize stationary industrial and e-mobility applications.

MEET C-MOTIVE

Sustainability

Green Technology With a Twist.

By using local and simple machine components, C-Motive is able to remove a large quantity of carbon emissions from the equation. Electrostatic motor technology has a lower environmental impact during operation and less embodied carbon within the raw materials when compared to other motors on the market.

Learn More

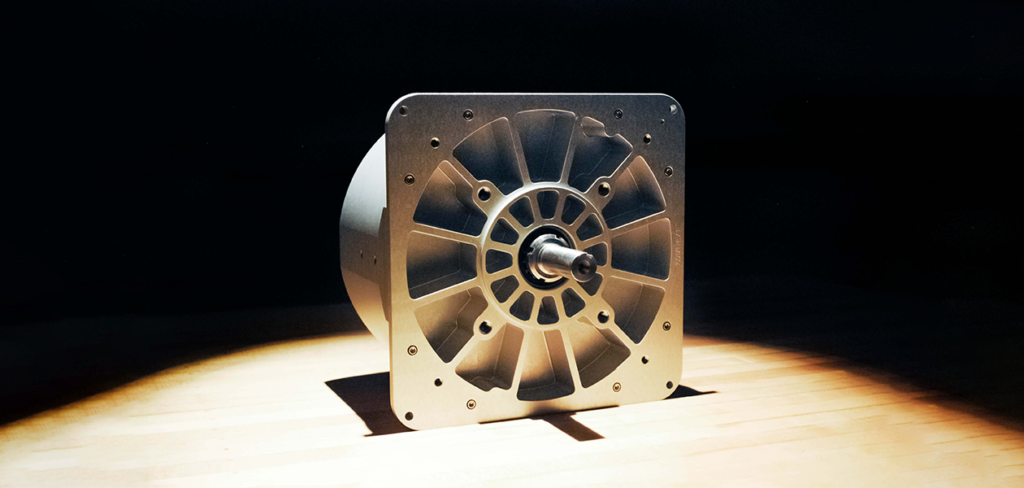

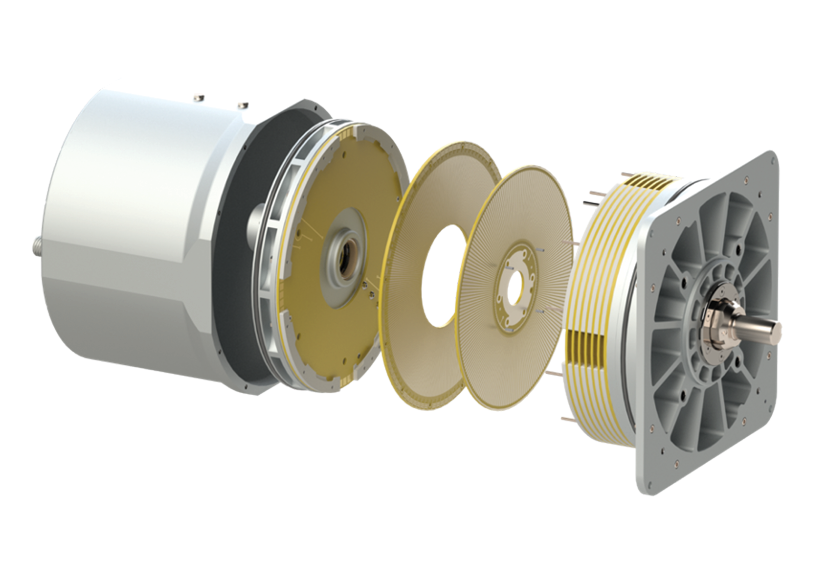

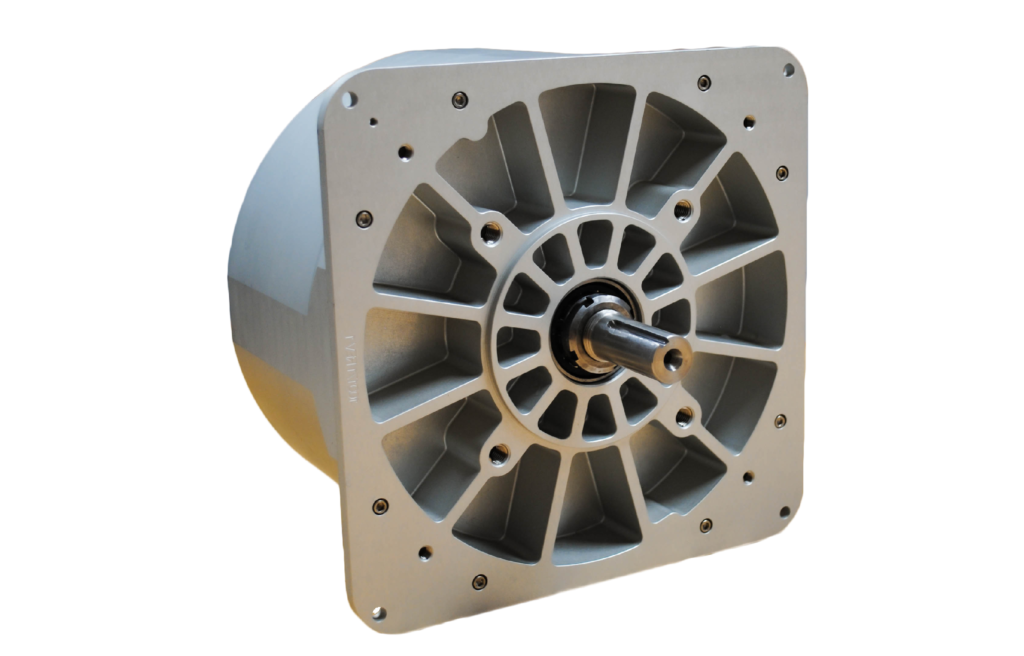

Technology

Modular, Scalable, Customizable Motors and Generators.

By harnessing the power of static cling, C-Motive has created a fundamentally unique motor that is highly efficient and specializes in high-torque, low-speed applications. With technology that has no torque ripple, audible noise, gearbox, or active cooling, the benefits are endless for a wide range of applications.

Learn More

Supply Chain

Materials that Matter.

Traditional electromagnetic motors on the market today are reliant on electrical steel, permanent magnets, and copper. These materials have experienced cost increases and are subject to limited supply sources. C-Motive’s technology has a regional and diverse supply chain built-in to keep things simple.

Learn More

Let's Talk.

Every application is different, and every customer has unique needs and requests. Tell us more about your needs and let’s talk about how electrostatic machines might be a good fit for your application, or sign up for our newsletter to get our latest updates sent right to your inbox.

Learn More